|

|

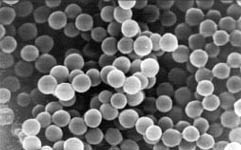

| STP® Surface Treatment Particles for toner enhancement |

|

STP® is a series of micronized toner additives that can offer a wide variety of benefits when added to dry toners for use in copy machines, facsimile machines and high-speed printers.

This unique product was developed by Nipon Paint Co., Ltd., one of the world's largest manufacturers of paints and coatings, based on their exclusive micro-gel technology.

|

| Value-Added Benefits of STP® include: |

Cleaning : Small toner particles often remain on drums. This residue is difficult to clean. Currently, silica, aluminum and iron oxide are used to clean the residue off the drums.

By adding STP® along with inorganic material to the toner, clean drums can be achieved without affecting the charge.

Anti-Blocking : Toner particles often stick together during transfer fusion at lower tempertures. The addition of STP® to the toner can prevent this from occurring.

Tribocharge : Fine-tuning of toner is possible by adding STP® to an existing toner formulation. The addition of STP® can enhance a positive or negative charge, which reduces or eliminates the need to reformulate existing toners to fit different machine models.

Flow : The addition of STP® can assist toner flow. The result is a cleaner, clearer image.

Anti-Filming : A thin layer of toner often remains on the surface of the drum. STP® gently remove this film without scratching the drum surface.

Low Fusion : By encapsulating toner with STP®, low temperature fusion is possible.

|

| The following standard samples can be provided for evaluation : |

| General properties of Micro Particle Series Powder Type |

|---|

| Copolymers | Cross Linking |

|---|

| Product Name |

FS-101 |

FS-102 |

FS-104 |

FS-201 |

FS-401 |

FS-501 |

FS-701 |

MG-151 |

MG-152 |

| Particle Diameter (nm) |

80 |

80 |

300 |

550 |

70 |

400 |

100 |

80 |

80 |

| Glass Transition Temp. (°C) |

65°C |

100°C |

108°C |

95°C |

102°C |

90°C |

78°C |

N/A |

N/A |

| Triboelectric Charge (µc/g) |

-70 |

-130 |

-55 |

-110 |

+80 |

+330 |

-120 |

-55 |

+45 |

| Component |

Acrylic |

Styrene Acrylic |

Styrene Acrylic |

Styrene Acrylicr |

Styrene Acrylicr |

Acrylic |

Fluoride |

Acrylic |

Acrylic |

| BET Surface Area (m/g) |

60 + 5 |

70 + 5 |

20 + 5 |

11 + 2 |

60 + 10 |

11 + 2 |

55 + 10 |

70 + 10 |

70 + 10 |

| Appearance |

White Powder |

White Powder |

White Powder |

White Powder |

White Powder |

White Powder |

White Powder |

White Powder |

White Powder |

| Moisture Content (wt. %) |

< 0.8 |

< 0.8 |

< 0.8 |

< 0.8 |

< 0.8 |

< 0.8 |

< 0.8 |

< 0.8 |

< 0.8 |

| Bulk Density (lbs. / ft) |

6.5 + 1.3 |

5.5 + 1.7 |

6.5 + 1.3 |

9.7 + 1.9 |

6.5 + 1.3 |

9.7 + 1.9 |

6.5 + 1.3 |

6.5 + 1.3 |

6.5 + 1.3 |

|

We can develop customized particles to meet your requirements,

based on the following design parameters: |

|

|

| Design Parameters of Micro Particles |

|---|

| Particle Diameter |

40nm - 1µ |

| Triboelectric Charge |

+400 µc/g |

| Tg |

40°C to 120°C(FS Series)

N/A(MG Series) |

| Melting Point |

Up to 270°C(cross linked) |

| Electric Resistance |

E13 - E16 |

| Appearance |

White Powder |

|

|

Please contact NPA if you are interested in exploring the benefits of our toner additives. By providing us with some basic information about the intended use and the benefits you hope to achieve, we can provide you with the appropriate standard samples that most closely fits your requirements.

Once you have examined the standard samples, we will work with you to develop customized particles unique to, and best suited for, your application.

|